Products List

Concrete Crushing Equipment

Author:liming Post Date:2013-4-25

Concrete Crushing Equipment

Concrete Crushing Equipment Cone Crusher:

Gyratory concrete crushing equipment, cone concrete crushing equipment works but only for breaking or crushing operations broken machinery. Nesting size uniformity crushing operations generally high crushing operations requirements, therefore, in the lower part of the crushing chamber shall be provided with a parallel zone at the same time, we must speed up the crushing cone cycle speed, so that the material in the parallel region by extruding more than once.

Relatively coarse crushing operations broken broken operations, after its broken loose volume have a larger increase. In order to prevent the crushing chamber may cause obstruction, increased nesting mouth in order to ensure that the premise of the nesting size, must be increased by increasing the diameter of the lower part of the crushing cone total nesting section.

Cone concrete crushing equipment discharge opening smaller, mixed with a compound non-broken material more likely to lead to an accident, a result, the crushing operation nesting size demanding liner wear timely adjustment nesting mouth, thus Cone concrete crushing equipment insurance and adjusting device of the machine is more necessary compared to crushing operations.

The springs insurance cone concrete crushing equipment overload, forcing cone shell spring compression and its own elevated, in order to increase the discharge opening, discharge non-broken. Nesting population adjustment by adjusting sleeve adjustment sleeve rotating solid-filled shell can be to drive the casing with the thread on its outer rise or fall, to change the size of the discharge opening. Insurance and adjust hydraulic cone concrete crushing equipment with hydraulic gyratory concrete crushing equipment.

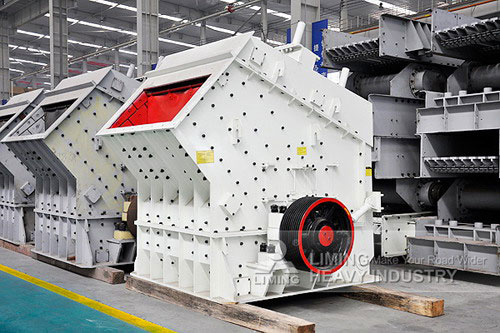

Concrete Crushing Equipment Impact Crusher:

Impact concrete crushing equipment is a rebound effect of the high-speed impact of the board hammer and counter plate material by repeated shocks and broken machinery. Hammer plate fixedly mounted on the high-speed rotation of the rotor, and counter plate arranged at different angles for several blocks along the crushing chamber.

Material into the role of the board hammer District, first by the first impact of the board hammer concrete crushing equipment initial and access to energy at the same time, high-speed rushed counterattack board. Materials and counter plate collision again broken, bounced back to board hammer District, by the impact of the board hammer again. So repeatedly, until it is broken into a desired particle size and discharged outside the machine. Compared with hammer concrete crushing equipment, impact concrete crushing equipment broken than the larger and more fully take advantage of the high-speed impact energy of entire rotor. Board hammer easy to wear, it is hard material crushing applications is limited, and is usually used to rough broken, breaking or crushing limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum and stone raw materials and other medium hard brittle materials below.

Concrete Crushing Equipment Mining Crusher:

Mining concrete crushing equipment crushing machinery total content of high capacity more than 50% a row compound particle size is greater than three millimeters. Invented by British Hengan. Coarse crushing operations are often divided into feeding and nesting size size broken, broken, and crushing. The gravel equipment used jaw concrete crushing equipment, impact concrete crushing equipment, impact concrete crushing equipment, compound concrete crushing equipment, single stage hammer concrete crushing equipment, vertical concrete crushing equipment, gyratory concrete crushing equipment, cone concrete crushing equipment, roll concrete crushing equipment machines, double roll concrete crushing equipment, combo concrete crushing equipment, concrete crushing equipment several molding.

Concrete Crushing Equipment Roll Crusher:

Roll concrete crushing equipment roller surface friction material broken into bite so bear squeeze or split and broken machinery. For coarse crushing or the need to increase the crushing ratio, often in the roll surface of the teeth or grooves to increase the splitting effect. Roll concrete crushing equipment usually divided into the number of roller single roll, double roll and multi-roll concrete crushing equipment, suitable for primary crushing, breaking or crushing of coal, limestone, cement clinker and feldspar in hard materials below.

Liming Concrete Crushing Equipment:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment, capable of producing various types of crusher and mill, and reached the leading level in the world. We are a trustworthy concrete crushing equipment manufacturer capable of producing all types of concrete crushing equipment, good quality and reasonable prices. Liming Heavy Industry production of concrete crushing equipment is a set of similar products at home and abroad, the successful experience, devote themselves to come up with an energy-efficient crushing equipment. Medium-sized concrete crushing equipment is one of the leading products of the company, especially in the design and production of large crusher mill at the absolute leading level at home and abroad.

If you need any help of concrete crushing equipment, please contact us directly. We aim to provide you with the best concrete crushing equipment and the most economical reasonable solution, our experts will provide technical assistance at any time for you. Looking forwards to establish a long-term business relationship with you.