Products List

Sand And Gravel Crushing Plant

Author:liming Post Date:2012-12-27

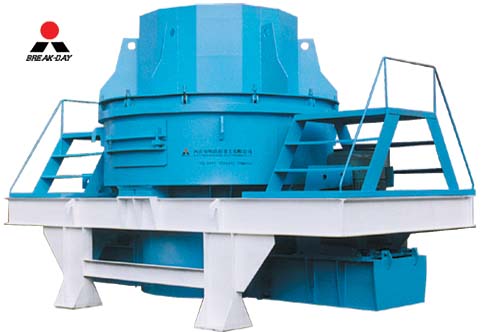

Sand And Gravel Crushing Plant

Sand and Gravel Crushing Plant Introduction:

Sand and gravel crushing plant equipment, mainly for soft or medium hard and extremely hard materials crushing, shaping a new crushing concept. It works in the U.S. Department of Pa Manle raised in Europe and the United States, has a variety of products, different in name, in our country, often referred to as vertical impact crusher. Such equipment more than 30 years of history, is widely used in metal and non-metal ores, cement, refractories, abrasives, glass raw materials, construction aggregate, artificial sand and a variety of metallurgical slag crushing and coarse grinding jobs, particularly in the in hard, extra-hard and abrasive materials such as silicon carbide, silicon carbide, sintered bauxite, magnesite and other broken, more than other types of crushers superiority. 10 of 500t / h production capacity range to fit almost any production requirements engineering mechanisms sand, cushion material, asphalt concrete and cement concrete aggregate production and mining grinding pre-crushing the ideal equipment.

Sand and gravel crushing plant performance characteristics.

The structure is simple and reasonable, since the strike crusher, ultra-low cost of use; unique bearing installation and advanced spindle design, the machine has a heavy load and the characteristics of the high-speed rotation. Have crushing, coarse grinding function; high reliability, tight security devices to ensure that the equipment and personal safety; smooth operation, noise, energy efficient, high crushing efficiency; material moisture content, moisture content of up to 8 percent; low wear and tear of wearing parts, all wearing parts are made of high-quality wear-resistant materials at home and abroad, and long service life. A small amount of wear parts made ????of extra-hard wear-resistant material, small size, light weight, easy to replace parts. Inside the vortex chamber airflow self-circulation, dust pollution. Impeller whirl crushing cavity lining material from significantly reduce the wear parts cost and maintenance workload. The production process, the stone can be formed to protect the bottom, the body no wear and durability. Installation and diverse, mobile installation. Products are cubic, bulk density, small iron contamination. Can be used for stone shaping machine.

Sand and Gravel Crushing Plant Working Principle:

Material from the feed hopper into the sand and gravel crushing plant, the material is divided into two parts by the sub-feeder, and in part by the middle of the sub-feeder into the high-speed rotation of the impeller, the impeller being rapidly accelerated acceleration of up to several hundred times the acceleration of gravity, then the speed of 60-70 m / s from the impeller three runner uniform projectile out, first of all with the broken part of the sub-feeder four weeks since the closing falling material impact, and with the impact to the vortex cavity lining materialson the material lining rebound, oblique impact to the top of the whirl chamber, but also to change its direction of motion, deflected downward movement of material emitted from the impeller form a continuous materials curtain. Such a material in the the whirl crushing cavity by twice as well as several times the probability of impact, friction and grinding crushing effect. The broken material is discharged from the lower part of the discharge opening. And form a closed cycle screening system, the three general circulation materials broken into 20 mesh. Material mutual self-impact crusher in the entire crushing process, not in direct contact with the metal components, but with the lining materials shock, friction and grinding, which reduces pollution angle, to extend the time of mechanical wear. Self-loop, the the whirl chamber internal clever airflow eliminates dust pollution.

Sand and Gravel Crushing Plant Application:

This product is widely used for making various kinds of mine, such as cement, fire-proof materials, aluminum soil, emery, glass raw materials, building sand, stone materials, and metallurgical slag. It is especially efficient to crush harder and causticity materials, such as carborundum, emery, and magnesium sand.

Liming Sand and Gravel Crushing Plant:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment, capable of producing various types of crusher and mill, and reached the leading level in the world. We are a trustworthy sand and gravel crushing plant manufacturer capable of producing all types of sand and gravel crushing plant, good quality and reasonable prices. Liming Heavy Industry production of sand and gravel crushing plant is a set of similar products at home and abroad, the successful experience, devote themselves to come up with an energy-efficient crushing equipment. Medium-sized sand and gravel crushing plant is one of the leading products of the company, especially in the design and production of large crusher mill at the absolute leading level at home and abroad.

If you need any help of sand and gravel crushing plant, please contact us directly. We aim to provide you with the best sand and gravel crushing plant and the most economical reasonable solution, our experts will provide technical assistance at any time for you. Looking forwards to establish a long-term business relationship with you.