Products List

Jaw Rock Crusher Plans

Author:liming Post Date:2012-11-16

Jaw Rock Crusher Introduced:

Jaw Rock Crusher Plans

The jaw crusher is the most widely used type of crusher has the advantages of large crushing ratio, product stone shape uniform, simple structure, easy maintenance. Jaw crusher is divided into coarse and fine broken two, to achieve the maximum compressive strength of the 320Mpa the materials carried broken.

Jaw Rock Crusher Category:

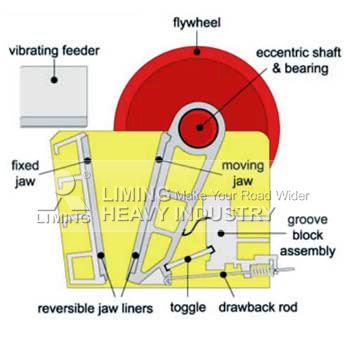

Common jaw rock crusher is two ways: on the move type under acting. On acting jaw rock crusher unchanged due to the width of the port of discharge, the work often clogged, affecting the normal work, so now been eliminated. Under acting jaw rock crusher concentrator. It is constituted by the following main components: a fixed jaw and the front wall of the rack, suspended on the shaft of the movable jaw, the eccentric shaft, the vertical rod, the toggle plate, the drive flywheel. Two jaw board the liner, with a spring lever, elbow board seat, adjust the block.

Jaw Rock Crusher Working Principle:

Motor through the belt so that the rotation of the eccentric shaft, the up and down movement of the vertical rod that is, when the vertical link up, driven by two brackets gradually stretched flat bracket to force the movable jaw to the fixed jaw forward, crushing chamber (ie composed of fixed jaw plate and moving jaw space) in the ore being squeezed, splitting, fold flexor and broken. Vertical link-down movement, toggle plate and movable jaw plate, by the force of the springs and tie rods to the back at the port of discharge increase, the ore is broken thus discharged. Visible jaw rock crusher is intermittently broken ore. The eccentric shaft of a turn each half cycle for crushing and subsequent half cycle for the row of ore. So it is compared with other continuous crushing machinery, power consumption greater mechanical efficiency is lower.

Jaw Rock Crusher Competitive Advantage:

1, Crushing chamber depth and no dead zone, increased capacity and output feed;

2, Broken than large, uniform particle size;

3, Gasket discharge opening adjustment device, reliable and convenient adjustment range, and increase the flexibility of the device;

4, The lubrication system is safe and reliable, easy to replace parts, maintenance workload is small;

5, Simple structure, reliable operation, low operating costs;

6, Energy-saving equipment: stand-alone energy-saving 15% to 30%, saving more than doubled;

7, The nesting population adjustment range, to meet the requirements of different users;

8, Low noise, less dust.

Liming Jaw Rock Crusher Plans:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment, capable of producing various types of crusher and mill, and reached the leading level in the world. We are a trustworthy jaw rock crusher manufacturer capable of producing all types of jaw rock crusher, good quality and reasonable prices. Liming Heavy Industry production of jaw rock crusher is a set of similar products at home and abroad, the successful experience, devote themselves to come up with an energy-efficient crushing equipment. Medium-sized jaw rock crusher is one of the leading products of the company, especially in the design and production of large crusher mill at the absolute leading level at home and abroad.

If you need any help of jaw rock crusher plans, please contact us directly. We aim to provide you with the best jaw rock crusher and the most economical reasonable solution, our experts will provide technical assistance at any time for you. Looking forwards to establish a long-term business relationship with you.