Products List

Jual Sillica Sand Powder Machine

Author:liming Post Date:2013-5-27

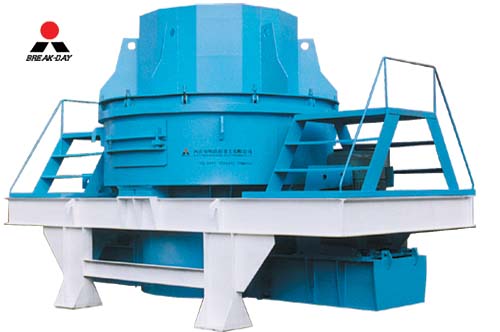

Jual Sillica Sand Powder Machine

Jual Sillica Sand Powder Machine Introduction:

Jual sillica sand powder machine, also known as impact crusher, the introduction of foreign advanced technology combined with working conditions in China R & D production, which is widely used in metal and non-metal ores, highway, water conservancy and hydropower, refractories, abrasives, glassceramic raw materials, urban construction aggregate, artificial sand and a variety of metallurgical slag crushing and coarse grinding jobs, especially in hard, extra-hard and grinding corrosive materials such as silicon carbide, silicon carbide, sintered bauxite, magnesite, etc., has more advantages than the other types of crushers.

Jual sillica sand powder machine is the earliest developed by crushing equipment, material from the impact, or materials with metal counterattack plate impact crusher. Native stone at stone "and" stone blacksmith crushing chamber, "stone at stone" and more used in the crushing of hard materials processing, production sand rate more than 40%, "stone blacksmith" and more used in hard materials crushing process more than 50% of the rate of production of sand, the the two cavity line structure can achieve mutual conversion in order to adapt to the different material crushing and processing.

Jual sillica sand powder machine is widely used in highways, high-speed railway, high-rise buildings, municipal, hydroelectric dam construction, concrete mixing station to provide high-quality sand and gravel aggregate, artificial sand and stone shaping field equipment.

Jual Sillica Sand Powder Machine Features:

1, The structure is simple, and the operating cost is low.

2, High efficiency, and low power consumption.

3, It is slightly influenced by the humidity of material, and the max humidity is 8%.

4, It is more suitable for crushing materials of mid-hardness and high-hardness.

5, Its product is of cubic shape, and the density of piling up is high and the iron pollution is low.

6, The working noise is less than 75 decibels and dust pollution is little.

Jual Sillica Sand Powder Machine Application:

This product is widely used for making various kinds of mine, such as cement, fire-proof materials, aluminum soil, emery, glass raw materials, building sand, stone materials, and metallurgical slag. It is especially efficient to crush harder and causticity materials, such as carborundum, emery, and magnesium sand.

Jual Sillica Sand Powder Machine Feeding Mode:

A, overflow into the material, impeller feed size the same. Such feed situation, to the amount of material to operate at full capacity (ie all motor power play) into the impeller further increase feed overflow into the whirl crushing cavity, impeller outside.

B, the waterfall fall into material feed particle size when the second feed particle size larger than the impeller on from two feed inlet, respectively Feeding.

Jual Sillica Sand Powder Machine Working Principle:

Jual sillica sand powder machine into the hopper, sub-feeders, eddy crushing chamber, impeller body, spindle assembly, the base transmission and motor consists of seven parts, stone rock principle, more materials for their own collision broken.

Material from the feed hopper into the jual sillica sand powder machine, the material is divided into two parts by the sub-feeder, and in part by the middle of the sub-feeder into the high-speed rotation of the impeller, the impeller being rapidly accelerated acceleration of up to several hundred times the acceleration of gravity , then the speed of 60-70 m / s from the impeller three runner uniform projectile out, first of all with broken by the impact of the part of the sub-feeder four weeks since the closing falling materials, and with the impact of the whirl cavity lining materials on the material lining rebound, oblique impact to the top of the whirl chamber, reflection, deflection downward movement of the collision with emitted from the impeller material again, such a material eddy the crushing cavity by twice as well as several chances to impact, friction and grinding crushing effect, finally lost the energy of the material discharged from the crushing cavity. Throughout the crushing process, the materials of mutual self-impact crusher, not in direct contact with the metal components, but with the material lining shock, friction and crushing, thus greatly reducing the wear and tear of equipment, extend the life of the machinery. The same time, the whirl chamber clever internal airflow self-circulation, but also to maximize the elimination of dust pollution.