Products List

Stone Crushing Process

Author:liming Post Date:2012-10-25

Stone Crushing Process:

Stone crushing process can be used for hard limestone, granite, basalt, river pebbles, smelting slag and other materials, aggregate and artificial sand stone application to apply to water, electricity, building materials, highway, urban construction and other industries. Combine various types of equipment, depending on the process requirements, to meet customer's different process requirements.

Stone crushing process equipment consists of: mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyors and other equipment. Liming Heavy the design stone crushing process is equipped with jaw crusher, impact crusher, and other major equipment is generally large device, equipped with cone crusher, dust removal equipment, etc. In addition to the meet customers different processing needs. Stone production line high degree of automation, large crushing ratio, high production efficiency, processing capacity was cube-shaped, broken products, low flakiness content, without internal cracks, engage the pressure is high. Simple equipment maintenance, consumable parts color is the newest high-strength wear-resistant materials, loss, long service life, can bring considerable economic benefits for customers.

Stone Crushing Process Workflow

Stone Crushing Process Workflow:

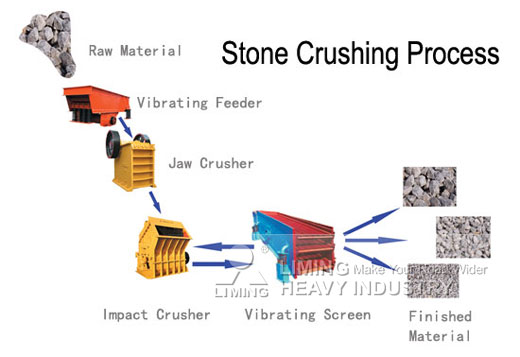

First, large pieces of stone by the silo that is evenly feeding coarse crusher feeder jaw crusher preliminary crushing production into a coarse material is then transported by belt conveyor to the impact crusher for further crushing, stone into after crushing vibrating screen pebbles of different specifications, does not meet the size requirements of stone material back into the impact crusher broken again, to form a closed-loop recycled many times. The stages can also be used to a cone crusher for crushing. To meet the size requirements stones sent to the finished windrow finished tape conveyor. Another product size is to be combined and graded according to the needs of users, for the protection of the environment, can be equipped with auxiliary dust removal equipment.

Liming Stone Crushing Process:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment, capable of producing various types of crusher and mill, and reached the leading level in the world. We are a trustworthy stone crushing process manufacturer capable of producing all types of stone crushing process, good quality and reasonable prices. Liming Heavy production of stone crushing process is a set of similar products at home and abroad, the successful experience, devote themselves to come up with an energy-efficient crushing equipment. Medium-sized stone crushing process is one of the leading products of the company, especially in the design and production of large crusher mill at the absolute leading level at home and abroad. If a stone crushing process and its related machinery and equipment you need or want to know stone crushing process, please contact our online staff. We will provide more information and better services.

Liming Stone Crushing Process Process Characteristics:

1, eliminating the need for a classes cutting, new feeder application GZD series vibrating feeder solve the feed silo "bridging" shed card and uniformity, reduce labor intensity workers and reduce belt wear, provided favorable conditions for high and stable yield.

2, new crusher This series of products has broken, product size uniform, reasonable structure, reliable operation, easy maintenance, operating costs and economic characteristics, and are widely used in mining, building materials, stone industry, smelting, water conservancy and other departments. A variety of materials, with breaking strength of not more than 350 MPa is the primary crushing preferred equipment.

3, the new Impact Crusher This series of product configuration after the coarse crusher, crushing ore, rock compressive strength less than 350 MPa, has a processing capacity, the fine characteristics of the discharge. Broken was the end of the cube, flakiness content within cracks. Is the device of choice for high-grade highways, water conservancy, airport and other industries the production of high-quality stone.

4, new vibrating screen YA Series circular vibrating screen is the latest generation of screening equipment designed by the company designed for quarry screening material stone, complete specifications of the series, the novel structure, strong exciting force, large processing capacity, sieve points, high efficiency, low noise, new design, sophisticated manufacturing the products durable, easy maintenance, selling in Southeast Asia. The device has been widely used in building materials, transportation, energy, cement, mining, stone and other industries.

5, the new conveyor has a conveying capacity, simple structure, easy maintenance, standardization of components, etc., which are widely used in mining, metallurgy, coal departments, used to transport loose materials or items, according to the the conveying process requirements can single conveyor can also be a belt conveyor or other conveyor machine tool equipment to form horizontal or inclined conveyor system to meet the different arrangement of the operating line needs. The belt conveyor can be used within an ambient temperature range of -20 ° C to +40 ℃, material temperature below 50 ℃. The Conveyor see with site conditions.