Products List

Oil Shale Crusher

Author:liming Post Date:2013-6-27

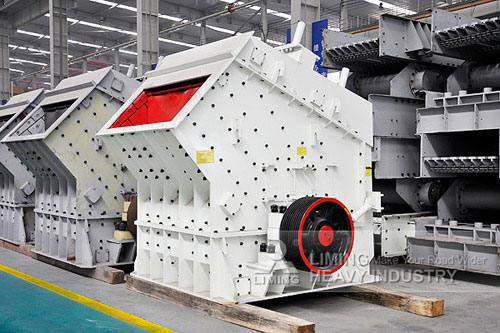

Oil Shale Crusher

Oil Shale Crusher Introduction:

Oil shale crusher (back-breaking) can handle particle size of not more than 500 mm, the compressive strength of not more than 350mpa various coarse, fine materials (granite, limestone, concrete, etc.), counter-breaking product was cube, widely usedin relatively high demand areas, highways, reservoirs, railways, airports and other stone shape more suitable for the production of higher road, water, electricity, construction and other industries with a stone. Is the ideal senior road surface and hydropower construction aggregate processing equipment. Years of usage Crusher for its excellent performance and good performance in the field of highway construction, hydraulic engineering and architectural gravel processing widely used.

Oil shale crusher crushing power to decide on the nature of the material, crushing ratio and productivity. Impact crushing ratio and productivity, there are many tong, such as the rotor speed, the shape of the crushing chamber, feed size. Crushing power of general empirical formula or to project power consumption measured units finished. Liming Heavy production oil shale crusher can process the ore particle size of not more than 120-500 mm, compressive strength less than 350 MPa, rock.

Oil Shale Crusher Performance and Use:

Oil shale crusher appears a little late,while it develops very rapidly. At present, it has been widely applied to medium crushing,fine crushing,also coarse crushing in cement, building materials, coal,chemical industry and mining.The reason why oil shale crusher develops so rapidly is for the following advantages:

High crushing ratio:the crushing ratio of oil shale crusher is about 30-40,even the max can be 150.While the max ratio of other crushers is less than 10.

Therefore, for the present popular three-stage crushing plant,if using oil shale crusher in it,there will only need one-stage or two-stage to finish the crushing,which greatly simplify the production process, save investment.

High crushing efficiency, low energy consumption: for impact strength of normal stuff is far lower than compressive strength,at the same time, when stuff is impacted by high-speed hammer and impact plate,stuff is crushed firstly along the joint interface and weak&vulnerable organization.Therefore its crushing efficency is high and electric energy consumption is low.

Homogeneous final product size,less excessive comminution.In the crushing process, larger stuff is crushed to a great extent, while smaller one is not crushed under some circumstances,so there is homogeneous final product size and less excessive comminution.

Selectively crushed. In the impact crushing process,useful minerals and gangue are firstly crushed along the joint interface in order to facilitate the separation of useful minerals,especially for coarse crushing of useful minerals, which is more remarkable.

Great adaptability. oil shale crusher can be used to process brittle stone,fibrous stone and medium hard stone,particularly suitable for brittle stone such as limestone,so it is proper to use oil shale crusher in cement and stone industry.

Small size, light weight, simple structure, easy maintenance.

For the above advantages,oil shale crusher is widely used all over the world.However if to process hard stone,the hammer and impact plate will be badly worn. In addition,oil shale crusher is a crushing equipment making use of high-speed rotation and impact,so it has high requiremnts for precision of mechanical parts, and also for static balance and dynamic balance in order to extend the service life.

Oil Shale Crusher Use and Maintenance:

In normal use, the operator adjusts the radial clearance between impact plate and hammer mainly according to wear pattern of hammer and final product size. With hammer worn,the final product will be gradually coarse. At present, our hammer and impact plant is made of high manganese steel.

In addition, the bearing of oil shale crusher should be installed strictly in accordance with our factory’s regulation,checking and adjusting the clearance of bearing and lubricating device,timely replacing sealing ring in order to ensure the normal operation of bearing.

Working Principle:

Oil shale crusher is a use of impact energy to break material crushing machinery.When the unit is operating, the motor driven rotor high-speed rotating materials into the active area of the plate hammer, impact crusher plate hammer on the rotor, and later was thrown counterattack device again broken, then from counterattack linerbounced back to the the board hammer district re-broken, and this process is repeated, the material descending into one, two, three, fight back cavity repeated broken until the materials are crushed to the required size of the discharge port. Adjust the gap between the frame and the rotor counterattack up to change the purpose of material discharging size and material shape.

Liming Oil Shale Crusher:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment, capable of producing various types of crusher and mill, and reached the leading level in the world. We are a trustworthy oil shale crusher manufacturer capable of producing all types of oil shale crusher, good quality and reasonable prices. Liming Heavy Industry production of oil shale crusher is a set of similar products at home and abroad, the successful experience, devote themselves to come up with an energy-efficient crushing equipment. Medium-sized oil shale crusher is one of the leading products of the company, especially in the design and production of large crusher mill at the absolute leading level at home and abroad.

If you need any help of oil shale crusher, please contact us directly. We aim to provide you with the best oil shale crusher and the most economical reasonable solution, our experts will provide technical assistance at any time for you. Looking forwards to establish a long-term business relationship with you.