Products List

Roller Mill Working Principle

Author:liming Post Date:2012-8-31

Roller Mill Introduction:

High Pressure Suspension Roller Mill is my chief engineer Mr. Bai Yinghui, wearable device experts on the basis of the experience of many years engaged in high fine powder processing, devoted themselves to developing new milling equipment, thus creating international industrial milling efficient, low power new era.

Roller Mill Application Scope:

High pressure hanging roller mill for crushing barite, limestone, ceramic, slag, etc. Mohs hardness of not greater than 9.3, humidity below 6% non-flammable mining, metallurgy, stone industry, building materials industry more than 280 kinds of material for high fine powder processing, product size is 80-425 mesh range adjustment (the smallest 1,000 head). The machine can add special device can produce 30-80 mesh coarse powder.

Roller Mill Structure:

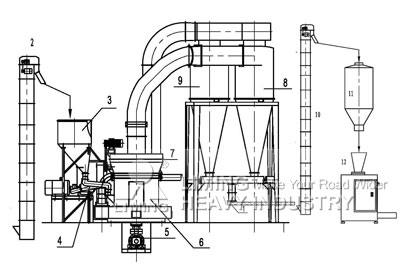

roller mill working principle

High pressure hanging roller mill mainly by the host, fine analysis machine, Blower, finished whirlwind plot powder, bag filter and link duct composition. According to user needs can also be equipped with broken machines, elevator, storage silo, electromagnetic vibrating feeder and electrical control cabinet and other auxiliary equipment. The host, roller assembly roller suspender through the cross arm shaft suspension, roll grinding hanger with the spindle and blade knife fixed contact, the pressure spring outer end face in the the roller bearings Room cantilever cross arm shaft fulcrum to force the grinding rollers pressed tightly in a circle on the surface of the grinding ring, when the motor through the gear driven spindle rotation, installed in synchronous rotation of the blade and roller blade knife, roller grinding ring round scroll rotation. Motor through the the gear driven analysis impeller rotation, the higher the speed of the impeller, the finer the powder sub-sub-elected.

Roller Mill Working Principle:

High pressure hanging roller mill mainframe, roll grinding hanger on fastening a 1000-1500 kg pressure spring. After starting work, grinding rolls around spindle rotation and high pressure spring and centrifugal force, keep grinding ring rolling, the rolling pressure is 1.2 times higher than under the same dynamic conditions Raimundo powder machine yield is much higher.

When grinding the material into the grinding chamber., The shovel blade fed between the roller and grinding ring from the RCC RCC after the powder with the circulating air blower into the analysis machine, qualified with the powder-gas inflow whirlwind powder which is finished, large particulate matter particles fall back regrinding. The circulating air blower to repeat the above process, I entered the Wind bag filter purification.

When the roller and grinding ring reach a certain wear high-pressure adjustment spring length to keep the constant grinding pressure between the roller and grinding ring. In order to ensure stable production and fineness.

Liming Roller Mill:

Liming Heavy Industry is committed to producing the best mechanical crushing equipment in China, capable of producing different types of roller mill. Liming roller mill working principle, leading the excellent performance of the grinding machine.

Liming Roller Mill Characteristics:

1, Production increased by 10% to 20% 1, compared to the same with the other mill under dynamic conditions, the grinding pressure grinding rolls of material improve 800-1200kg high pressure spring action.

2, Mohs hardness of less than 9.3 of mineral materials can be crushed.

3, A wide range of product size is the particle size of the rough up to 0.613 mm (30 mesh), the particle size is generally up to 0.033 mm (425 mesh), a small number of the most fine materials up to 0.013 mm (1,000 head).

4, The dust effect fully meet national standards for dust emissions.

5, The analysis machine easy to adjust.

6, The grinding device of overlapping multi-stage sealing, good sealing performance.

If you need roller mill or a similar product, please contact us. We will provide more information and better services.